Copper Wire Rods are essential components in various industrial and electrical applications. Selecting the right grade and size is crucial to ensure performance, efficiency, and longevity of your project. Whether you’re working in electrical wiring, automotive parts, or construction, understanding the types, grades, and specifications of copper wire rods is key to achieving the desired results.

In this comprehensive guide, we will explore the different grades of Copper Wire Rods, their industrial applications, factors influencing the selection of the right size, and practical tips to make the best choice for your specific requirements.

What Are Copper Wire Rods?

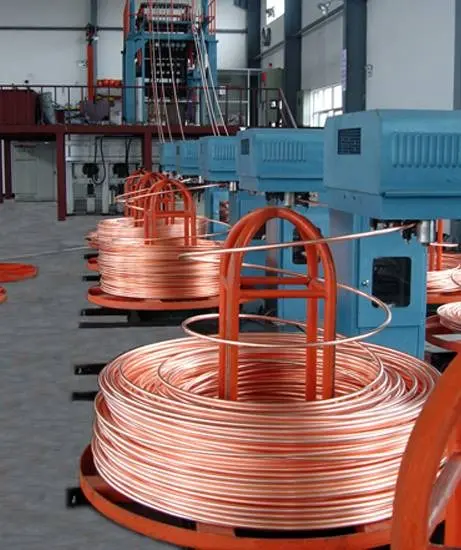

Copper wire rods are cylindrical wires made from high-purity copper. They are produced through a continuous casting and rolling process, resulting in uniform diameters suitable for further processing into wires, cables, or other components.

These rods are widely used due to copper’s exceptional electrical conductivity, thermal conductivity, and corrosion resistance. Their applications range from electrical and electronic industries to construction and automotive manufacturing.

Types of Copper Wire Rods

Copper wire rods are classified based on purity, mechanical properties, and alloy composition. Choosing the right type is crucial for the intended application. Here are the main types:

1. Electrolytic Tough Pitch (ETP) Copper Wire Rods

- Composition: Minimum 99.9% copper content

- Properties: Excellent electrical conductivity, good tensile strength

- Applications: Electrical wires, power transmission, and transformers

2. Oxygen-Free Copper (OFC) Wire Rods

- Composition: 99.95% pure copper with very low oxygen content

- Properties: High conductivity, corrosion-resistant, better ductility

- Applications: High-end electrical components, audio cables, and sensitive electronics

3. Copper Alloy Wire Rods

- Composition: Copper mixed with small percentages of metals like tin, silver, or phosphorus

- Properties: Enhanced strength and wear resistance while maintaining good conductivity

- Applications: Automotive parts, machinery, and industrial equipment

Factors to Consider When Choosing Copper Wire Rods

Selecting the right copper wire rods involves evaluating several key factors.

1. Electrical Conductivity

Electrical conductivity is the primary factor for any copper rod used in wiring or electrical applications.

- For high-efficiency power transmission, OFC copper wire rods are preferred.

- For standard industrial wiring, ETP copper rods are sufficient.

2. Mechanical Strength

Some applications require rods that can withstand high mechanical stress.

- Copper alloys are ideal for environments where durability and tensile strength are crucial.

- Consider the tensile strength and elongation of the rod before final selection.

3. Diameter and Size

Copper wire rods come in various diameters, usually ranging from 5mm to 25mm.

- Smaller diameters are suitable for fine electrical wiring.

- Larger diameters are preferred for heavy-duty industrial and construction purposes.

4. Corrosion Resistance

Copper naturally resists corrosion, but environmental conditions can affect performance.

- Oxygen-free copper provides better resistance against oxidation.

- For outdoor or marine applications, consider copper alloys with improved corrosion resistance.

5. Thermal Conductivity

High thermal conductivity is essential for heat dissipation in electrical applications.

- Pure copper rods have the highest thermal conductivity.

- Alloyed rods may have slightly reduced thermal efficiency but higher mechanical strength.

Common Grades of Copper Wire Rods

Understanding the grades will help you choose the best fit for your application. Some commonly used grades include:

- C11000 (ETP Copper) – Excellent for general-purpose electrical applications

- C10200 (Oxygen-Free Copper) – Ideal for high-performance electronics

- C14500 (Phosphorized Copper) – Perfect for resistance welding and industrial machinery

- Copper Alloys (C17200, C18150) – Used in spring, automotive, and mechanical applications

Industrial Applications of Copper Wire Rods

Copper wire rods are used across multiple industries due to their versatility.

1. Electrical and Electronics Industry

- Power cables, transformers, motors

- Circuit boards and connectors

- High-performance audio cables

2. Automotive Industry

- Wiring harnesses

- Battery components

- Electric vehicle motors

3. Construction and Infrastructure

- Building wiring

- Lightning conductors

- Roofing and plumbing

4. Industrial Machinery

- Mechanical components

- Motors and generators

- Machinery requiring wear-resistant copper alloys

How to Select the Right Size of Copper Wire Rods

Choosing the correct size is as important as selecting the right grade. Follow these steps:

Step 1: Determine Application Requirements

- Electrical load

- Mechanical stress

- Environmental conditions

Step 2: Consult Standards

- ASTM, BS, and IEC standards provide specifications for wire rod diameters and tolerances

Step 3: Match Diameter to Application

- Fine wires: 5–10 mm rods

- Medium wires: 10–15 mm rods

- Heavy-duty wires: 15–25 mm rods

Step 4: Consider Future Expansion

- Factor in possible load increases to prevent overheating or mechanical failure

Tips for Purchasing Copper Wire Rods

- Buy from reputable suppliers to ensure consistent quality and purity.

- Verify certificates and testing reports.

- Consider bulk purchasing for cost efficiency.

- Check for compliance with industry standards.

Conclusion

Choosing the right grade and size of copper wire rods is critical for achieving optimal performance in any application. By considering factors such as conductivity, mechanical strength, diameter, and corrosion resistance, you can ensure your project runs smoothly and efficiently. Suppliers like sumssolution.com provide detailed specifications and high-quality options to help you make the right choice. Investing time in selecting the right rod today can prevent costly replacements and performance issues in the future. Remember, understanding the material, its specifications, and industrial requirements is the key to success.