HVAC drawings serve as the blueprint for coordinating complex building systems, ensuring that heating, ventilation, and air conditioning components integrate smoothly with electrical and plumbing infrastructure. Without accurate HVAC design services, construction teams face a maze of conflicts that can derail timelines and budgets.

This comprehensive guide explores why HVAC drawings services USA are essential for successful MEP coordination, the key components that make them effective, and how modern tools are revolutionizing the coordination process. Whether you’re a contractor, architect, or building owner, understanding these fundamentals will help you avoid costly mistakes and deliver superior building performance.

The Critical Role of Accurate HVAC Drawings

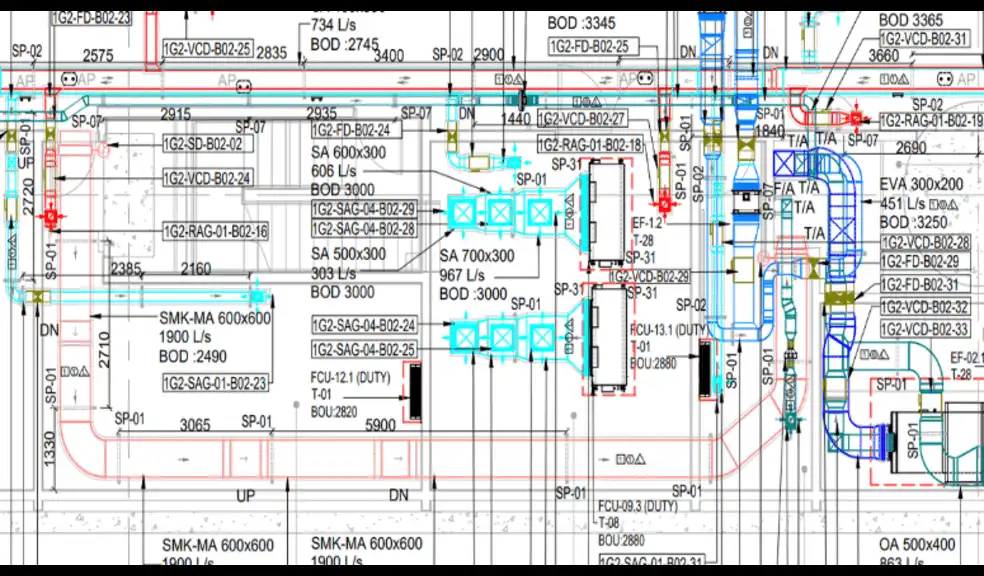

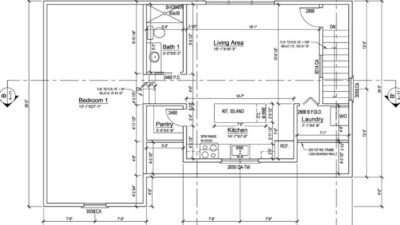

Accurate HVAC drawings function as the central nervous system of building construction, connecting all mechanical systems in a coordinated network. These technical documents do more than show where ducts and equipment go—they create a roadmap for seamless system integration.

Foundation for System Integration

HVAC drawings establish the spatial relationships between mechanical components and other building systems. They define clearances, access requirements, and maintenance zones that electrical and plumbing systems must respect. Without this foundation, trades work in isolation, leading to conflicts that surface during installation when changes are most expensive.

Risk Mitigation Through Precision

Precise drawings identify potential conflicts before construction begins. They reveal where a large supply duct might interfere with a structural beam or where electrical conduit routes could block HVAC equipment access. This foresight prevents the finger-pointing and change orders that plague poorly coordinated projects.

Regulatory Compliance Assurance

Building codes require specific clearances, ventilation rates, and safety measures for HVAC systems. Accurate drawings demonstrate compliance with these requirements, streamlining the permit approval process and preventing costly code violations during construction.

Essential Components of Effective HVAC Drawings

Professional HVAC drawings services incorporate several critical elements that enable successful MEP coordination. Understanding these components helps project stakeholders evaluate drawing quality and completeness.

Equipment Layout and Sizing

Equipment schedules detail the exact specifications, dimensions, and installation requirements for each HVAC component. This includes mechanical rooms, rooftop units, air handlers, and terminal devices. Proper sizing ensures adequate capacity while preventing oversized equipment that wastes energy and space.

Ductwork and Piping Systems

Detailed ductwork layouts show supply, return, and exhaust air paths throughout the building. Pipe routing indicates chilled water, hot water, and condensate drainage systems. These drawings must include pipe sizes, insulation requirements, and slope specifications for proper drainage.

Control System Integration

Modern HVAC systems rely on sophisticated control networks that require coordination with electrical systems. Drawings must show sensor locations, control panel positions, and communication pathways that integrate with the building’s automation infrastructure.

Structural Considerations

HVAC drawings must account for structural elements like beams, columns, and floor penetrations. Equipment loads, vibration isolation requirements, and seismic bracing details ensure mechanical systems don’t compromise building integrity.

Facilitating Seamless MEP Coordination

HVAC drawings serve as the coordination hub that brings mechanical, electrical, and plumbing trades together. This integration process requires careful planning and communication between all disciplines.

Clash Detection and Resolution

Advanced HVAC design services use 3D modeling to identify conflicts between systems before construction begins. These digital models reveal where a supply duct conflicts with electrical conduit or where plumbing risers interfere with HVAC equipment access. Early detection allows designers to resolve conflicts through routing adjustments or equipment repositioning.

Space Planning and Allocation

Building space is a finite resource that must be allocated efficiently between MEP systems. HVAC drawings establish ceiling heights, mechanical room layouts, and corridor requirements that other trades must accommodate. This spatial coordination prevents the chaos of unplanned installations that compromise system performance.

Scheduling and Sequencing

Construction sequencing depends on understanding how different trades interact. HVAC drawings inform installation schedules by identifying which systems must be installed first. For example, large ductwork typically requires installation before electrical cable trays, and this sequence must be clearly communicated through the drawings.

Quality Control Standards

Detailed drawings establish quality standards that guide installation and testing procedures. They specify connection methods, testing requirements, and performance criteria that ensure systems operate as designed. This documentation becomes the benchmark for commissioning and system startup.

Measurable Benefits of Effective Coordination

Proper HVAC coordination through comprehensive drawings delivers quantifiable benefits that justify the investment in quality design services.

Cost Savings

Well-coordinated projects typically experience 15-20% fewer change orders compared to poorly planned projects. These savings result from reduced rework, minimized delays, and fewer material modifications during construction.

Timeline Compression

Coordinated installations proceed more efficiently because trades aren’t waiting for conflicts to be resolved. This streamlined process can reduce construction schedules by 10-15%, delivering buildings to owners sooner.

Performance Optimization

Properly coordinated HVAC systems operate more efficiently because they’re installed according to design specifications. This results in lower energy consumption, reduced maintenance costs, and improved occupant comfort.

Liability Reduction

Clear drawings reduce disputes between trades by establishing definitive installation requirements. This documentation protects all parties by providing a clear reference for resolving conflicts and determining responsibility.

Common Coordination Challenges

Despite the benefits of good coordination, several challenges can derail MEP projects when not properly addressed.

Communication Breakdowns

Different trades often use varying terminology and standards, leading to misunderstandings. HVAC drawings must use clear, standardized symbols and conventions that all trades understand.

Design Changes and Revisions

Building projects evolve throughout design and construction, requiring constant updates to drawings. Managing these changes across multiple disciplines requires robust document control procedures.

Technology Integration Gaps

Legacy CAD systems may not integrate well with modern Building Information Modeling (BIM) platforms. These compatibility issues can create coordination gaps that lead to conflicts.

Skill and Experience Variations

Not all HVAC consultants have equal experience with complex coordination projects. Finding qualified hvac consultant near me requires careful evaluation of past project experience and coordination capabilities.

Modern Tools and Technologies

Technology is transforming how HVAC drawings are created and coordinated with other building systems.

Building Information Modeling (BIM)

BIM platforms create intelligent 3D models that automatically detect conflicts between systems. These tools enable real-time coordination between trades and provide accurate material quantities for cost estimation.

Cloud-Based Collaboration

Cloud platforms allow distributed teams to access current drawings and models from anywhere. This real-time access ensures everyone works from the latest information, reducing coordination errors.

Augmented Reality (AR) Applications

AR technology overlays digital models onto physical spaces, helping installers visualize complex systems before installation. This technology reduces interpretation errors and improves installation accuracy.

Automated Compliance Checking

Software tools can automatically verify that drawings comply with building codes and industry standards. This automation reduces manual checking time and improves compliance accuracy.

Selecting the Right HVAC Design Services

Choosing qualified HVAC drawings services requires careful evaluation of several factors that impact coordination success.

Experience and Expertise

Look for consultants with demonstrated experience in similar project types and building complexities. Their portfolio should show successful coordination of complex MEP systems.

Technology Capabilities

Ensure the consultant uses current BIM software and collaboration tools. Their technology stack should integrate well with other project team members.

Communication Skills

Effective coordination requires clear communication between all trades. Evaluate the consultant’s ability to explain complex technical concepts and facilitate coordination meetings.

Quality Assurance Procedures

Ask about their quality control processes and how they ensure drawing accuracy. Look for firms that conduct regular internal reviews and clash detection analysis.

Building Success Through Coordination

HVAC drawings are far more than technical documents—they’re the foundation for successful building construction. When properly executed, they transform chaotic construction sites into orchestrated symphonies of coordinated activity.

The investment in quality HVAC design services pays dividends throughout the project lifecycle. From reduced construction costs to improved building performance, effective coordination creates value that extends far beyond initial construction.

Success in MEP coordination requires commitment from all project stakeholders to prioritize accuracy, communication, and collaboration. By understanding the critical role of HVAC drawings and investing in quality design services, building owners can avoid the costly mistakes that plague poorly coordinated projects.

The future of construction depends on our ability to integrate increasingly complex building systems efficiently. CAD Drafting provides the roadmap for this integration, ensuring that our buildings perform as designed while creating healthy, comfortable environments for occupants.