Aircraft landing gear plays a critical role in ensuring safe takeoffs and landings. This system bears immense stress during every flight, making regular maintenance essential for reliability. Landing gear repair is a structured process involving inspection, repair, and testing to maintain functionality and safety. Understanding this process highlights its importance in keeping aircraft operational and passengers safe.

Why Is Landing Gear Repair Essential?

Landing gear endures intense pressure during operations, making it prone to wear and tear. Without timely repair, issues like corrosion, cracks, or component failure can jeopardize an aircraft’s safety. Regular maintenance ensures functionality and prevents costly breakdowns. By addressing problems early, landing gear repair enhances operational efficiency and extends the lifespan of this critical system.

Detailed Inspection of Landing Gear

The repair process begins with a thorough inspection of the landing gear. Technicians use advanced tools to detect structural issues, worn-out parts, or corrosion that may compromise safety. Non-destructive testing methods are commonly used to identify hidden problems without damaging the components. Inspections ensure that even minor issues are addressed promptly, maintaining the system’s integrity.

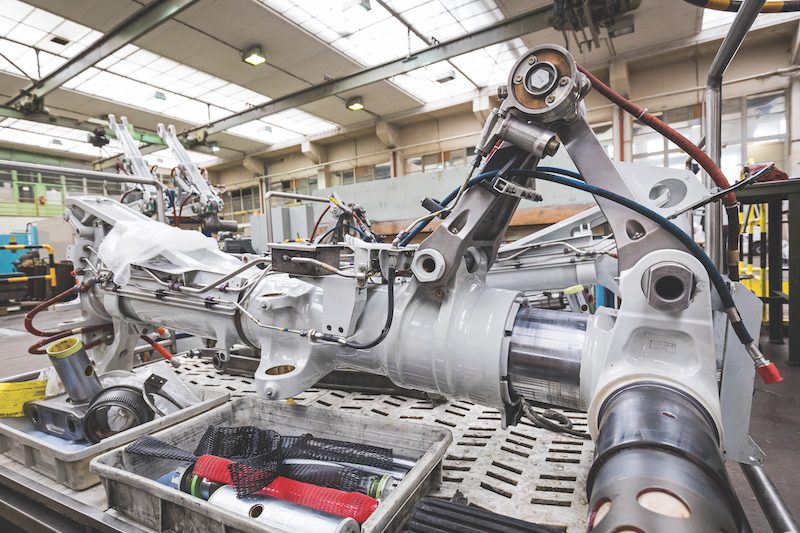

Disassembly and Assessment of Components

After inspection, the landing gear is disassembled into its parts. This allows technicians to evaluate each component in detail, including wheels, struts, and hydraulics. Damaged or worn-out parts are identified for repair or replacement. Disassembly ensures that every landing gear element is appropriately examined, leaving no room for oversight during the repair process.

Repair or Replacement of Parts

Once damaged components are identified, technicians decide whether to repair or replace them. Repairs might include welding, machining, or applying protective coatings to restore functionality. If parts are beyond repair, they are replaced with new ones to ensure the landing gear meets safety standards. This step is crucial for restoring the system’s strength and reliability.

Reassembly and Alignment

After repairs or replacements, the landing gear is reassembled with precision. Technicians align each part carefully to ensure seamless functionality. Proper reassembly is essential to prevent operational issues and ensure the system works smoothly under pressure. This step requires expertise and attention to detail to guarantee the landing gear performs as expected.

Testing and Final Quality Checks

Before being cleared for operation, the repaired landing gear undergoes rigorous testing. Technicians simulate real-life conditions to confirm the system’s performance and safety. Hydraulic systems, alignment, and braking mechanisms are thoroughly tested to ensure reliability. Quality checks verify that the landing gear complies with regulatory standards and is ready for safe use.

Documentation of Repairs and Maintenance

Every step of the landing gear repair process is meticulously documented, including inspection reports, repair records, and test results. Documentation not only ensures compliance with aviation regulations but also helps track maintenance history. These records are vital for monitoring the landing gear’s performance over time and planning future repairs.

Conclusion

Landing gear repair is a structured process designed to maintain aircraft safety and efficiency. Each step, from inspections to final testing, ensures the system functions reliably under demanding conditions. Regular maintenance prevents unexpected failures, extends the lifespan of critical components, and enhances passenger safety. By prioritizing proper landing gear repair; aviation professionals uphold the industry’s highest safety standards.