concrete, although a very resistant material, should be polished frequently to keep it in perfect condition, making it look much more beautiful and attractive. But how to polish concrete? Concrete polishing involves using an abrasive composed of industrial diamonds on rough concrete surfaces to obtain a much more modern and sophisticated appearance.

Industrial diamonds come in different shapes and sizes. The size of the industrial diamond and the grit number are inversely proportional to each other, i.e. discs with larger diamonds have a smaller grit and vice versa. The rougher the floor, the lower the grit. For polishing a floor , we use higher grits with smaller diamonds. Thanks to the polishing technique, all the performance of the construction material can be improved. To do this, all imperfections need to be removed by sanding and polishing the surface until it is smooth. There are 2 types of concrete polishing machines:

- Traditional concrete polisher , ideal for surface preparation

- The power trowel , recommended for finishing floors. The power trowel can be manual or piloted.

important: Looking for reliable residential concrete services in Golden, CO? Get expert solutions for driveways, patios, sidewalks, and more. Contact us today for a free estimate!

Steps to polish concrete

Concrete can be polished dry or wet , but first of all it is important to prepare the concrete surface to be polished, following these steps:

- Evaluate the hardness of minerals. This will help you determine whether the concrete is soft, medium or hard and help you use the right tools.

- Clean the surface, removing stubborn stains with an industrial scrubber and water.

- Repair any damage or cracks with special mortar.

- Polish with coarse grit , using a coarse grit (500) polishing disc for sanding

- Switch to a fine-grit polishing pad . It is recommended to use circular motions to work over the entire floor.

- Use an extra-fine grit polishing disc for the final stage, which will give it a very nice, glass-like shine.

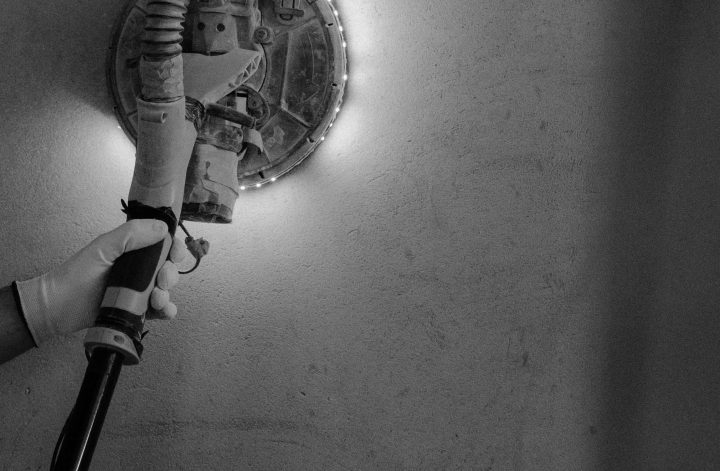

- Use the grinder to apply polish.

For polishing concrete floors, it is necessary to have the necessary machinery , such as a concrete polisher , using specific abrasives to sand and polish the concrete floor . For small surfaces, renting a polisher or purchasing a second-hand one is an option if you don’t own one. However, for larger areas, it’s more efficient to hire a concrete polishing company to handle the task. Very important: before using the polisher, have protective equipment, dust mask, gloves, safety glasses, earplugs. It is important to polish the floor progressively, starting with the lowest grains and ending with the highest.

Is it better to polish concrete dry?

Dry or wet polishing ? These are the two existing forms of polishing. In dry polishing, water is not added to the process, which generates a lot more dust. Only when the situation requires it and it is known that there are no health risks, can part of the polishing be carried out dry . Sometimes, one may find oneself faced with a seriously damaged concrete slab , with a really significant level of wear. This may be due to a lack of maintenance or due to the fact that it has endured intense and prolonged activity.

important: Need a trusted concrete service company near Parker, CO? We specialize in high-quality concrete installations for driveways, patios, and more. Get your free quote now!

If the wear or deterioration is severe before the polishing phase, a new tread layer must be applied. If the problem is due to the poor quality of the materials, only dry polishing will be possible to recover the concrete pavement. Dry polishing is very impractical, so it is usually carried out with a wet process where water is poured onto the pavement and it is polished and sanded with a trowel. Wet polishing is much more efficient by keeping the dust at ground level. There are three types of finishes for concrete:

- Mate

- Satin

- Bright

Each finish involves several polishing steps using increasingly finer diamonds. After each phase, the floor must be cleaned with an industrial scrubber , which collects the sludge produced by polishing and leaves the floor clean. Halfway through the process, a densifier is applied to reinforce the concrete surface, and finally, an impregnating seal is applied to make the floor more resistant to the absorption of liquids. Finally, the floor is polished to achieve a shiny, eye-catching and spectacular finish.