The ongoing challenge in manufacturing is to produce high-quality parts affordably and effectively. This problem is directly addressed by progressive die stamping, which provides an economical, accurate, and quick fix.

Although it is a technique that revolutionises the conventional process of metal forming, it is frequently hidden in technical details and technical language. A metalworking technique called progressive die stamping uses a sequence of dies to stamp a metal strip to produce complex pieces.

A separate operation is carried out at each station in the progressive die until the final portion is formed. This technique is widely used in the automotive, electronics, and aerospace industries because it is perfect for creating large quantities of progressive die stamping parts. Continue reading about the progressive die stamping and how parts are made:

What is Progressive Die Stamping?

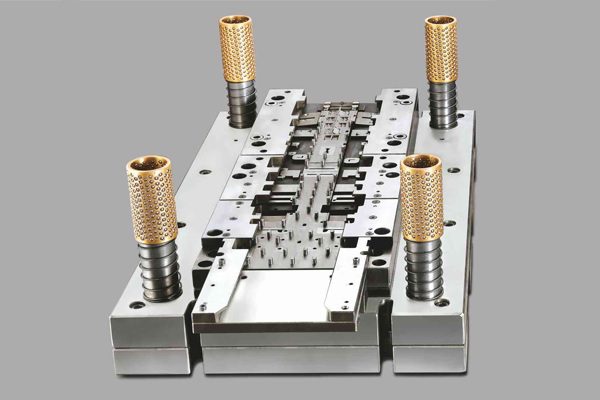

Using a stamping die progressive die stamping is a metal stamping method that shapes and cuts raw metal sheets. The component comprises multiple workstations that each carry out one or more tasks. Various operations can be carried out using the progressive die, including cutting, coining, punching, bending, lancing, shaving, extruding, drawing, and embossing.

As the name implies, progressive die stamping involves several progressive stages in which an automatic feeding system presses the raw material concurrently and progressively. Each step builds on the one before it to get the required shape. These phases all follow the same general structure, although minor differences may exist.

How Parts Are Made?

Ultra-high tolerance standards are attained at each process stage using following procedures.

Design & Layout of Stock Strips

To start, progressive die stamping parts makers use sophisticated computational models to build the progressive die. Optimising the location of each punch, bend, and hole on the blank strip shapes the graphical model into a completed tool.

Die Set and Tool Steel Machining

After the stock stamping die design is finished, the die blocks are made using CNC machining techniques by precise measurements. They undergo rigorous quality control before manufacturing material is committed, and they offer incredibly accurate part repeatability.

Secondary Processing: Grinding & Heat Treating

Heat treatments are used to strengthen parts by raising them over the critical transition temperature of the alloy. After that, the item is quickly cooled, which increases its dimensional stability and endurance. Grinding can also be used for parts that need even more surface quality or dimensional accuracy.

Wire EDM

A controlled metal spark further shapes the die blocks using an electrically charged brass wire. With cutting tolerances of ±2 µm, wire EDM operations may produce complex forms, angles, and curves. They can also create surfaces with Ra 0.1 µm.

Die Assemblies

After completing all required tool parts, an engineer uses precision instruments to assemble the die per the exact requirements of the original design.

Stamp Components

The completed die is then assembled in a stamping press. As the metal strip passes through the die, one step builds upon the other. The manufacturing process is finished when the metal strip is precisely formed through cutting, punching, and bending.

Package and Ship

The finished pieces are now prepared for shipment. Automated packaging machinery can increase productivity and precisely count and weigh boxes for every order.

Key Advantages of Progressive Die Stamping

Increased Speed:

A continuous material supply through various die stations designs progressively die stamping parts. In comparison to conventional machining, this enables you to produce a greater number of parts faster. This stamping process gives you the lowest cycle time per part for big volume parts.

Reduction of Scrap:

Metal stamping progressive die components require various forming techniques, including coining, bending, and punching, to produce the final item. Due to the large volume of material used, relatively little scrap is produced. For part makers, this makes it the most economical material.

Reliability in Accuracy and Precision:

Progressive die stamping is a well-known method for producing goods with accurate tolerances and consistent quality. Due to the dies accuracy and the controlled stamping process, each part is a replica of the last, which is crucial in industries where consistency is valued highly.

Faster Setup:

The progressive die stamping design process requires much less time than traditional stamping techniques. In traditional stamping, complex parts take many setups, tool changes, and die changes to manufacture, and in a single progressive die operation, the same results can be obtained.

Winding Up

Progressive die stamping is an advanced production technique that blends accuracy, effectiveness, and adaptability. It is evident why this procedure is preferred for mass-producing metal parts of superior quality once one is aware of its essential elements and steps. Progressive die stamping still meets the need for precisely manufactured components in the automotive, aerospace, and electronics industries.